Why rotor temperature matters more than you think

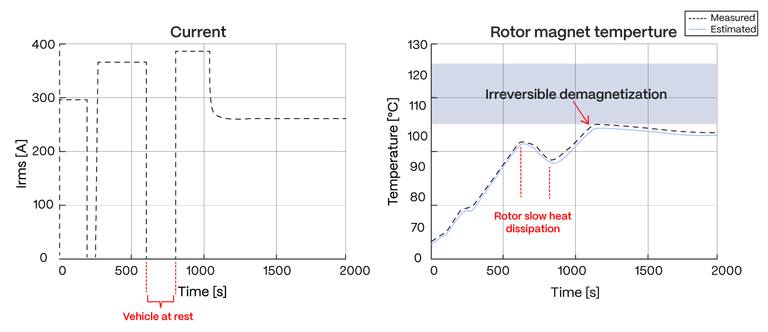

In modern electric drivetrains, rotor magnets often operate close to their thermal limits. Unlike the stator, which exchanges heat quickly with its cooling system, the rotor has a much slower thermal dynamic. This mismatch creates a subtle but critical problem in everyday driving conditions: start–stop cycles.

When the driver halts for a significant period - say, to run into a grocery shop- the stator has time to cool. The rotor, however, retains much of its heat. When the vehicle restarts, traditional estimation frameworks face a blind spot: the true rotor thermal state is unknown, because no real-time update occurred while the powertrain control unit was shut down. Over multiple stop phases, this can lead to an insidious build-up of rotor temperature that edges toward the critical threshold—without any warning from conventional estimators.

The limits of conventional estimation

Historically, solving this would require either invasive physical sensors on the rotor (often impractical or impossible) or complex, high-fidelity simulations like Finite Element Analysis (FEA). While incredibly accurate, these models are computationally intensive and too slow to run in real-time.

Today’s industry practice often relies on simplified thermal networks, sometimes combined with well-known Kalman filters. These tools are useful in steady operation, but often generalize poorly under changing conditions, and in a start–stop scenario, their limitations become apparent. When the system is powered down, no measurements are available, and the observer effectively freezes. Upon restart, the estimator must re-converge, but the true rotor state may already have drifted far from the assumed initial condition. The result is a lagging, sometimes unreliable estimate.

The observer initialization problem

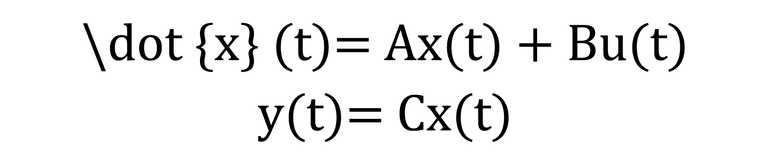

From a control-theoretical perspective, this challenge can be framed as a problem of initial condition mismatch in state-space observers.

A thermal network designed to approximate a rotor thermal dynamic can be expressed in standard form:

where:

- x(t) represents the internal thermal states

- u(t) are the heat generation and cooling inputs,

- y(t) are the measurable or estimated outputs.

An observer attempts to reconstruct x(t) from limited y(t). The difficulty arises when the motor restarts after a stop: the true state x(t0) has evolved through passive cooling, while the observer’s internal state \hat{x}(t0) has remained frozen. This discontinuity at initialization forces the observer to spend precious cycles catching up; cycles during which the estimation may be dangerously misleading.

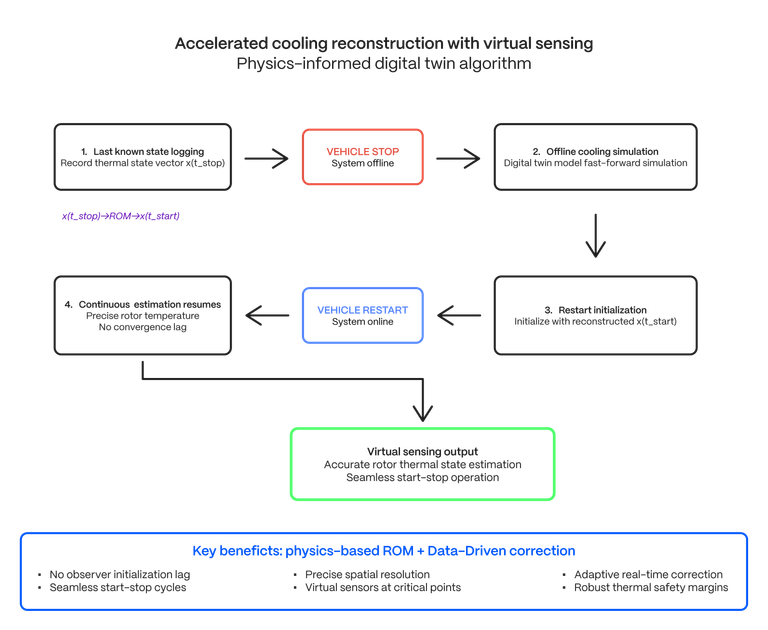

Accelerated cooling reconstruction with virtual sensing

This is precisely where virtual sensing, backed by a physics-informed and data-driven digital twin, shines. Instead of treating stop phases as a blackout, the digital twin uses its knowledge of thermal dynamics to “fast-forward” the system evolution offline. We could summarize the procedure as follows:

1. Last Known State Logging: Before shutdown, the software records the full thermal state vector x(tstop).

2. Offline Cooling Simulation: Using first-principles system dynamics and the internal state-space representation, the model simulates the elapsed time the vehicle was at rest. This reconstructs how the rotor cooled down.

3. Restart Initialization: At the next start, the temperature estimation framework does not begin with a frozen or guessed state. Instead, it is initialized with the reconstructed x(tstart), accurately reflecting the cooled-but-still-warm rotor.

4. Continuous Estimation Resumes: From this well-aligned baseline, the virtual sensor delivers precise rotor and magnet temperatures with no convergence lag.

Beyond averages: exact virtual sensors

Another decisive advantage is spatial resolution. While thermal networks can provide only average rotor values, a digital twin is capable of encoding into its framework a rigorous physical replica of the real motor, derived from a Reduced Order Finite Element Model, enabling virtual sensors placed at specific rotor or magnet positions. This precision matters because local hotspots, not just global averages, define the true thermal limits of the machine.

Predictive under uncertainty: the hybrid digital twin framework

Even with accurate Reduced Order Model (ROM) dynamics and correct restart initialization, reality always contains unmodeled disturbances: fluctuating ambient conditions, manufacturing tolerances, or non-ideal cooling paths. This is where the scientific machine learning and data-driven methodologies come into play.

Running alongside the first-principles model, a lightweight specialized neural network learns the systematic difference between predicted and measured signals. In essence, it acts as a nonlinear estimator, adapting in real time to capture effects the ROM alone cannot. We discussed this complementary tool in detail in a previous article.

Combined with the accelerated restart logic, it ensures the estimator remains both physically grounded and adaptively corrected, no matter how operating conditions shift.

Why this matters in real operation

In city driving, stop–start conditions are the norm. Each idle phase allows the stator to cool while leaving the rotor thermally “charged.” Without correction, estimators underestimate rotor temperature, masking a progressive heating trend. Over time, this can push the rotor dangerously close to its critical limit.

Virtual sensing prevents this blind spot. By combining state logging, accelerated cooling reconstruction, virtual sensors at critical rotor positions, and data-driven discrepancy correction, it ensures a trustworthy and continuous picture of rotor health—even when the system itself is offline.

From Risk to Reliability

For engineers, the implications are clear:

- Conventional Thermal Networks + Observer: frozen states, lagging convergence, only average rotor estimates, limited adaptation capability.

- First-Principles Virtual Sensing + Physics-Driven AI: seamless initialization, precise state reconstruction, virtual sensors at exact rotor locations, adaptive correction of unmodeled time-varying boundary conditions.

The result is a safer, more reliable estimation framework, one that keeps pace with the real physics of start–stop operation rather than lagging behind it.

The future of rotor thermal management

As electric vehicles evolve, thermal safety margins will shrink while performance demands rise. By equipping digital twins with accelerated cooling reconstruction and data-driven discrepancy correction, we close one of the last major blind spots in rotor thermal monitoring.

The result is a more resilient and reliable thermal estimation framework that accurately keeps pace with the real-world physics of high-performance operation, ensuring both safety and efficiency.

At Newtwen, we are developing advanced virtual sensing frameworks tailored for high-performance electric drivetrains. If you’d like to explore how our hybrid digital twin technology can be integrated into your system designs, explore our website and get in touch with our engineering team.